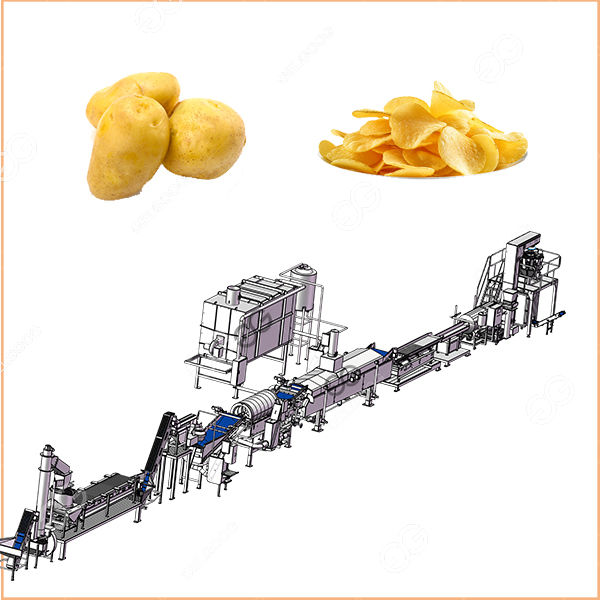

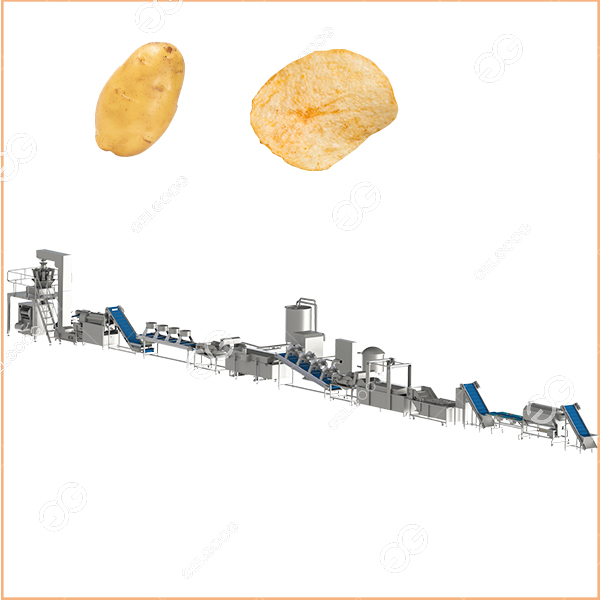

The economode potato chips line revolutionized the snack manufacturing industry by automating key processes, enhancing efficiency, and ensuring consistent quality. This advanced machinery encompasses a series of interconnected modules, each designed to perform specific tasks seamlessly.

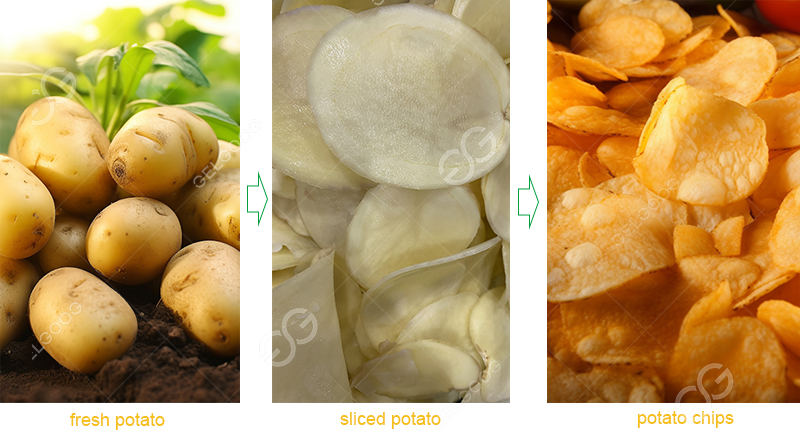

Potato chips processing flow:

Washing and peeling→slicing→blanching→frying→cooling→seasoning and packaging

- Washing and peeling: The process begins with the washing and peeling of potatoes. Advanced potato washing machine efficiently removes dirt and peels, ensuring clean and uniform potatoes for slicing.

- Slicing: Next, the potatoes are precisely sliced into thin, uniform slices. Automated slicers maintain consistency in thickness, a crucial factor in achieving the perfect crunch in every chip.

- Blanching: Sliced potatoes undergo blanching, a process where they are briefly submerged in hot water. This step removes excess sugars and starches, ensuring uniform frying and enhancing the final product’s texture and taste.

- Frying: The blanched potato slices are then conveyed into frying machine, where they are submerged in hot oil. Automated temperature control ensures optimal frying conditions, resulting in crispy and evenly cooked chips.

- Seasoning and packaging: Once fried to perfection, the potato chips pass through seasoning drums, where they are coated with a precise amount of seasoning. Finally, automated packaging machines weigh, seal, and label the potato chips, readying them for distribution.

Benefits of economode potato chips line:

The adoption of automatic potato chips lines offers numerous benefits to manufacturers, distributors, and consumers alike:

- Increased efficiency: Automated processes significantly reduce the need for manual labor, thereby increasing production efficiency and lowering operational costs.

- Consistent quality: By eliminating human error, potato chips lines ensure consistent quality in every batch of potato chips, meeting stringent standards and delighting consumers.

- Scalability: With the capacity to produce large quantities of potato chips in a short timeframe, automatic potato chips lines facilitate scalability, enabling manufacturers to meet fluctuating demand without compromising quality.

- Enhanced food safety: Advanced technology and stringent quality control measures minimize the risk of contamination, ensuring the safety and integrity of the final product.

As a potato chips production line supplier, we provide customers with customized services. According to customer needs and factory layout, we can customize equipment for customers.

Reviews

There are no reviews yet.