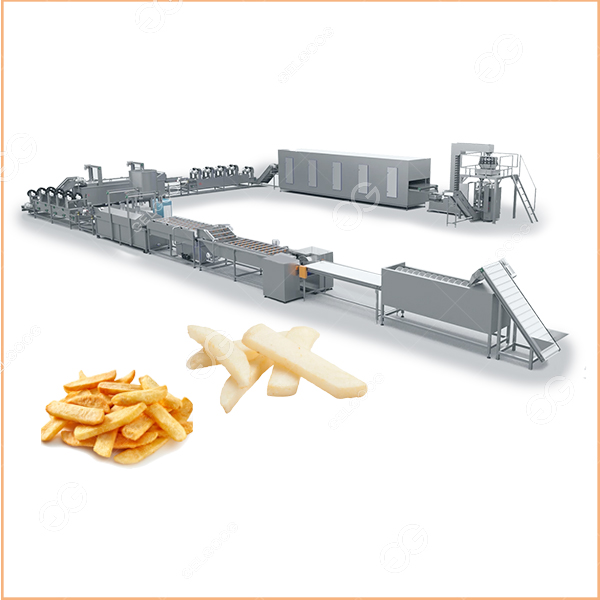

The full automatic frozen french fries lines with different processing capacities provided by our company can be designed and adjusted according to the actual needs of customers. Common processing capacities are: 100kg/h, 300kg/h, 500kg/h. 800kg/h, 1000kg/h,

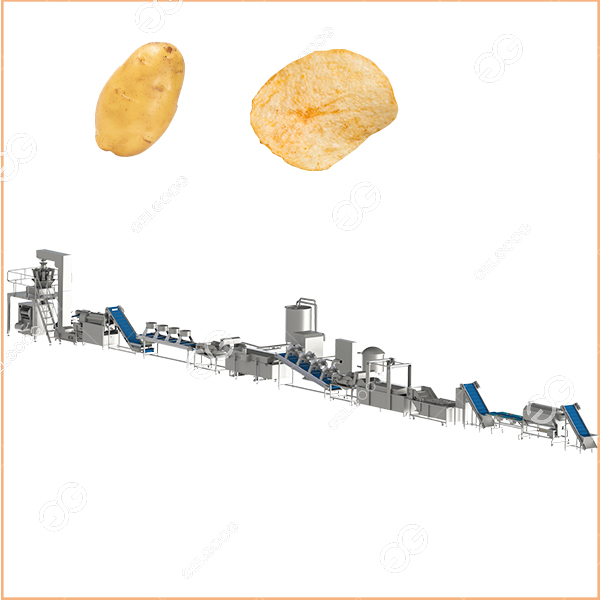

- Raw material: fresh potatoes

- The technical process of frozen french fries production line: selection → cleaning→peeling→cutting→blanching→cooling→draining→frying→deoiling→quick freezing→packaging

- The composition of machines for frozen french fries: bubble cleaning machine, peeling machine, strip cutting machine, continuous blanching machine, air drying machine, frying machine, degreasing machine, quick-freezing machine, etc.

Machine Introduction Of Frozen French Fries Processing Plant

- Potato hoist: Automatically lift potatoes, which is convenient and fast.

- Potato cleaning and peeling machine: a fully automatic potato brush peeling and cleaning machine is used to achieve peeling and cleaning at the same time.

- Slicing machine: automatic french fries cutting machine, the cutting size of french fries can be adjusted.

- Conveyor: Convey the cut fries to the blanching machine.

- Blanching machine: Wash off the excess starch on the surface of the fries to prevent oxidation.

- Vibrating drainer: After blanching, the surface moisture needs to be removed.

- French fries frying machine: automatic continuous frying machine, which can realize automatic frying of french fries, with good color and crisp taste after frying.

- Vibrating oil drainer: Vibrate to remove excess oil.

- Air cooling and cooling: Cool the fries sufficiently so that they can enter the freezer.

- French fries freezer: Quick-freeze in the French fries freezer.

- Frozen french fries packaging machine – according to the customer’s requirements, the packaging of the quick-frozen fries is fully automatic.

Working Video Of Full Automatic Frozen French Fries Line

Below is the working video of this frozen french fries processing plant. It can be seen from the video that this production line has very good production efficiency. It is very efficient to process potatoes, which can effectively reduce labor costs and production costs.

Features Of Machine For Frozen French Fries

- Fully automatic operation, simple operation, easy to use and less failure rate.

- The material of each machine is excellent and has a long service life.

- Provide customized design solutions for free.

- The quality of the finished product after freezing is very good, and it is an ideal frozen french fries production line.

If you want to get more details about this full automatic frozen french fries line and free quotation, please contact us and we will send it to you as soon as possible.

Technical Data

| Product Name | Frozen French Fries Production Line |

| Final Product | Frozen French Fries |

| Raw Material | Fresh potatoes |

| Capacity | 200 kg/h(Can be customized) |

| Working Shop | >300m2, height>4m |

| Voltage | 380/50Hz/3Phase |

| Power | 250kw(Customized) |

| Workers | 6-8 workers |

| Heating | Gas(Can be customized electricity) |

Reviews

There are no reviews yet.