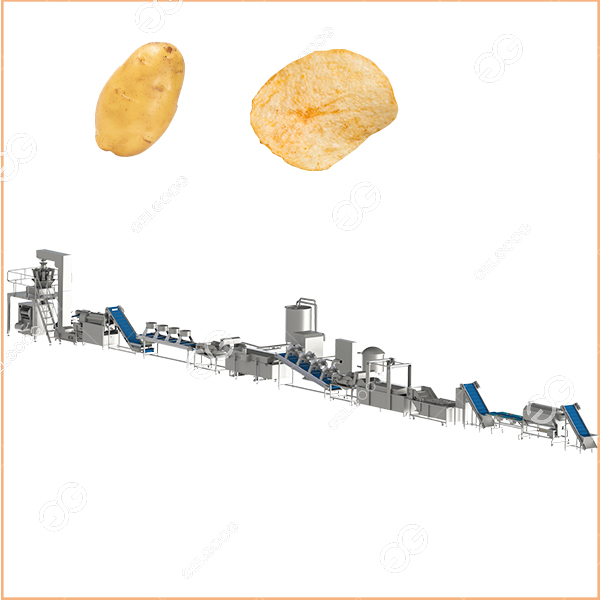

Designed to streamline your production process and deliver consistently high-quality chips, this automatic potato chips production plant is engineered for excellence.

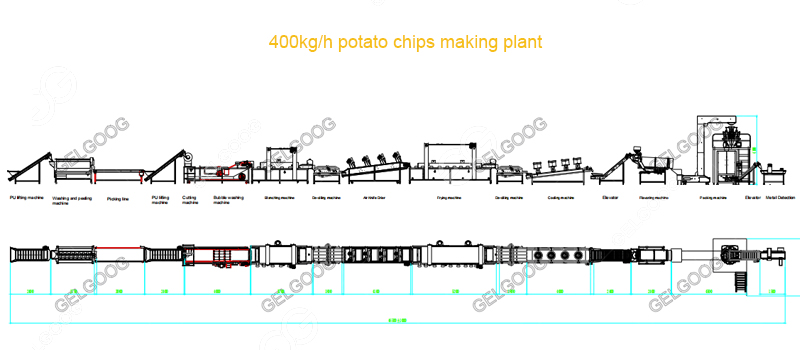

Automatic Potato Chips Production Plant Working Flow:

Washing → Peeling → Slicing → Rinsing → Dehydrate → Frying → Seasoning → Cooling → Packing

- Cleaning: Pour the potatoes into the feed port and remove stones, sand, etc. on the conveyor belt. After cleaning, it is sent to the cleaning machine through the lifting bucket to clean the surface soil and dirt, and then sent to the peeling machine for peeling.

- Peeling: Peeling loss is generally 1% to 4%. It is required to remove all the skin and the potato pieces will have a smooth appearance after peeling. Peeled potatoes also need to be washed.

- Slicing and rinsing: After slicing with a microtome, spray it with high-pressure water to remove the starch on the surface of the slices. Then bleach to protect the color.

- Dehydration: Shake off the moisture attached to the surface of potato slices.

- Frying: Frying of potato chips can be done in continuous production. The frying temperature is generally controlled at 180~190℃, and the frying time should generally not exceed 1 minute. Different batches of potato chips should be inspected and adjustments made.

- Cooling and packaging: After the potato chips are fried and seasoned, they are cooled on the belt conveyor and then packaged.

Automatic Potato Chips Production Plant Key Features:

- Automated processing: Say goodbye to manual labor-intensive processes. The production plant automates key stages of potato chips manufacturing, including washing, peeling, slicing, frying, seasoning, and packaging, ensuring uniformity and efficiency.

- High capacity: With a high-capacity design, this heat and control potato chips line is capable of processing large volumes of potatoes, making it ideal for both small-scale and large-scale production facilities.

- Customizable options: Tailor the production line to meet your specific needs and preferences. From adjusting slicing thickness to customizing seasoning application, our system offers flexibility to accommodate various chip styles and flavors.

- Advanced control systems: Featuring advanced control systems, the automatic potato chips production plant allows for precise monitoring and adjustment of key parameters such as frying temperature, conveyor speed, and seasoning distribution, optimizing chip quality and production efficiency.

Heat and Control Potato Chips Line Benefits:

- Increased productivity: By automating repetitive tasks, the production line boosts productivity, allowing you to meet growing demand without compromising on quality.

- Consistent quality: With precise control over processing parameters, our system ensures uniformity in chip size, texture, and flavor, enhancing customer satisfaction and brand reputation.

- Cost savings: By streamlining operations and reducing labor costs, our production line offers significant cost savings over time, contributing to improved profitability.

Upgrade your potato chips manufacturing operation with our automatic potato chips production plant and embark on a journey of efficiency, consistency, and profitability.

Reviews

There are no reviews yet.