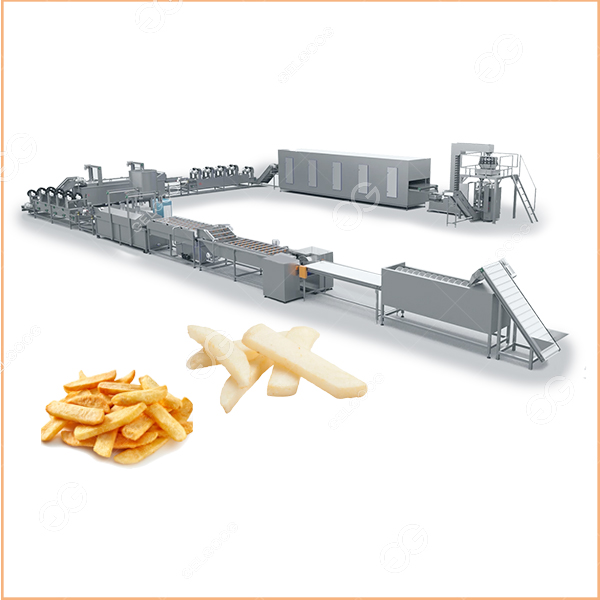

The fresh potato cutting and packing production line is mainly composed of a potato washing and peeling machine, potato cutting machine for potato, blanching and air drying machine, potato vacuum packing machines. The finished product style of its packing can be customized according to needs: potato strips, potato cubes, potato diced, potato chips, potato chips, etc.

Processing Flow Of Fresh Cutting Potato Processing Line

Potatoes→cleaning and peeling→cutting potatoes into strips/cutting potatoes into cubes →washing and drying→vacuum packing

Introduction Of Fresh Potato Cleaning Cutting Vacuum packing Processing Line

①Potato washing and peeling machine: Put the selected fresh potatoes into this machine for cleaning and peeling. The brush is used for cleaning, and it is equipped with a cleaning spray system to flush the waste in time and clean the brush to improve efficiency. After the work is completed, the material is automatically discharged from the discharge port to realize continuous production. It can be provided with a visible cover for easy observation. Potatoes are clean and beautiful after washing.

②Potato cutting machine for potatoes: There is a variety of cutting machines to choose from: the potato fries slicer can cut potatoes into strips, and the size of the fries can be adjusted. Potato slicers can get potato chips, and the slice size can be improved by adjusting the blade. Potato Dicing machine can get potato cubes.

③Blanching machine: The cut potatoes need to be blanched in a blanching machine, which can effectively inhibit the activity of enzymes, reduce the degree of oxidation, and protect the color. The temperature and time of the blanching machine are adjustable.

④ Air drying machine: The blanched potato strips/potato pieces need an air dryer to remove the moisture on the surface. This machine uses the wind generated by the fan to blow off the moisture on the surface of the material or reduce the surface temperature of the material.

⑤Potato vacuum packing machine: The use of vacuum packing machines for packing can effectively extend the shelf life of the product and keep it fresh for a longer time. Zero friction, zero wear, and higher efficiency can be achieved in the vacuum packing process.

Advantages Of Fresh Cutting Potato Processing Line

- The main part of each machine of this production line is made of high-quality stainless steel material, which has a long service life.

- Reasonable and beautiful appearance design, high efficiency, energy saving, environmental protection, and efficient packing speed.

- It can effectively save labor costs and is one of the most popular product lines for potato processing

- Energy-saving and easy maintenance. There are professionals to guide the installation throughout the process, allowing you to buy with confidence.

If you need this kind of processing line or want to get a free quote, please leave us a message.

Reviews

There are no reviews yet.