The industrial potato washing machine provided by our company uses a brush to wash the material and is equipped with a spray device. After washing, the material can be screwed out. It can complete cleaning, polishing and peeling at the same time. It is a commonly used machine in potato processing. This spiral-type potato washing and peeling machine can also be used for peeling other root vegetables and fruits, such as potatoes, carrots, sweet potatoes, tapioca, yams, beets, etc.

Characteristics Of Potato Peeling Machine

- The appearance is generous and good-looking, and it is made of 304 stainless steel material.

- The cleaning time and speed can be adjusted

- Equipped with a cleaning spray system to flush the waste and clean the hair roller in time,

- There is a water collecting tray at the bottom, which is convenient for mobile phone waste.

- A screw propulsion device can be added to match the independent feeding port

Advantage Of Industrial Potato Washing Machine

- Brushes can be customized according to requirements: soft brush, super-soft brush, hard brush, emery roller, different brush materials and different brush shapes can be suitable for different materials. Continuous production can be achieved, with a visual upper cover, which is easy to observe the cleaning of potatoes.

- Strong cleaning ability, potatoes are fully cleaned and peeled, sand, dust and other impurities can be fully removed without hurting the material.

- The potato peeling machine is well designed and easy to keep clean for easy maintenance.

Application Of Industrial Potato Washing Peeling Machine

This potato cleaning and peeling machine are widely used in the fruit and vegetable processing industry. It can complete various effects such as cleaning and peeling potatoes by changing the brush. It is also suitable for other root and stem fruit and vegetable products. The cleaned potatoes can be used for cutting, frying, quick freezing, and the finished products can be potato chips, french fries, and so on. Our company is a professional supplier of the potato washing machine. If you want to know more about this potato cleaning and peeling machine, please leave us a message!

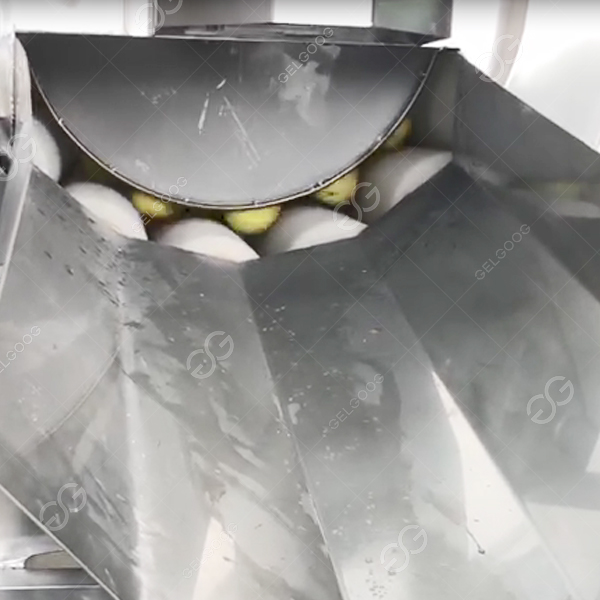

Working Principle And Video Of Industrial Potato Washing Machine

The design method of screw injection is adopted to make the potatoes move forward automatically during the process of cleaning and peeling. At the same time, there is also high-pressure water washing. After washing and peeling, the finished product is automatically discharged by the screw.

Technical Parameter

| Potato Brush Washing Machine | ||||||

| model | Net length of the wool roller | Length of hair roller | Diameter of hair roller | Motor Power | Spiral power | Dimensions(MM) |

| GG-SX800A | 945 | 800 | 120 | 1.1 | / | 1500×850×900 |

| GG-SX1000A | 1145 | 1000 | 120 | 1.1 | / | 1700×850×900 |

| GG-SX1200A | 1345 | 1200 | 120 | 1.5 | / | 1900×850×900 |

| GG-SX1500A | 1645 | 1500 | 120 | 2.2 | / | 2200×850×900 |

| GG-SX2000C | 2145 | 2000 | 120 | 3 | 0.37 | 2700×850×1500 |

| GG-SX2600C | 2745 | 2600 | 120 | 4 | 0.37 | 3300×850×1500 |

Reviews

There are no reviews yet.