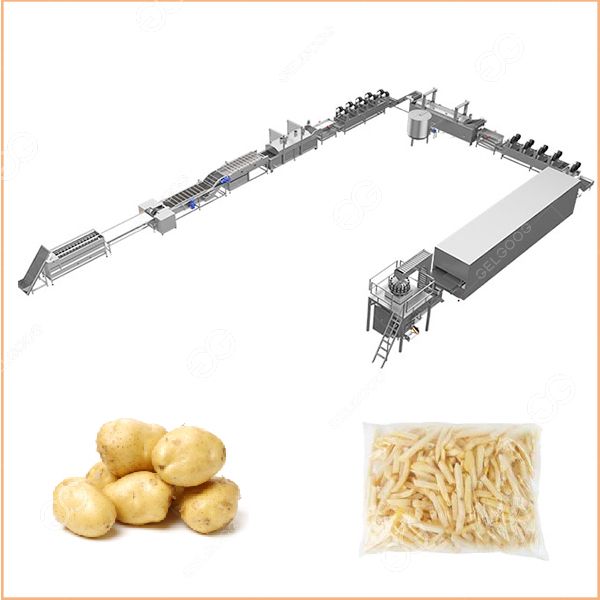

The frozen french fries processing line provided by our company is a fully automatic and complete frozen french fries solution, which can help customers better develop their quick-frozen french fries business. The optional output requirements are: 300kg/h, 500kg/h, 800kg/h, 1000kg/h, 1500kg/h.

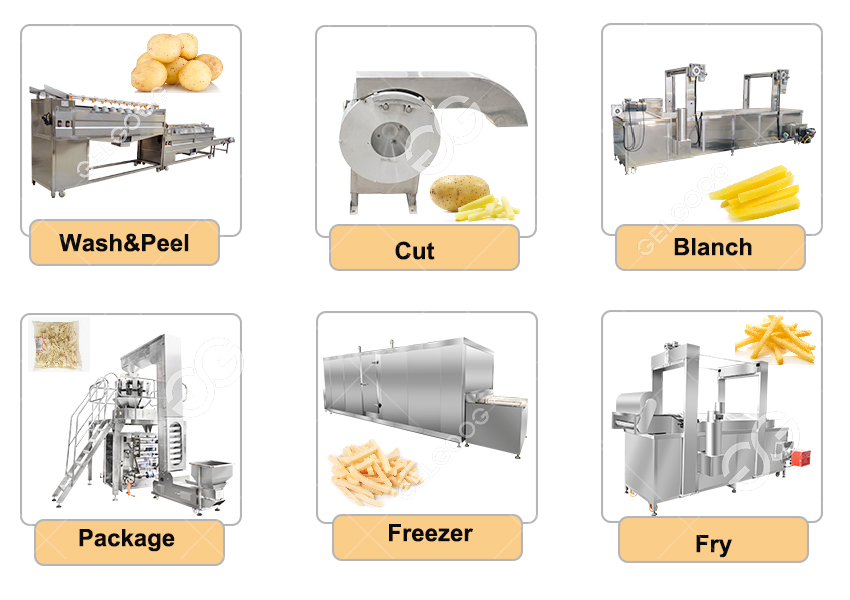

Frozen French Fries Manufacturing Process

The following is the detailed manufacturing process of frozen french fries:

Lifting → Rough washing and stone removal → Peeling → Picking and conveying → Cutting → Water bucket elevator → Flat roller to thinning → Vibrating screen to remove short → Rinse → Blanching → Vibration draining → Air knife air dryer → Lifting → Frying → Vibration Draining oil → air knife air dryer → air cooling conveying → vibrating cloth → quick freezing → conveying → packaging

Machine Introduction Of Frozen French Fries Processing Line

The main machines included in the manufacturing process of frozen french fries are: cleaning and peeling machine, cutting machine, blanching machine, vibration draining machine, air drying machine, frying machine, degreasing machine, quick-freezing machine, packaging machine.

①Potato cleaning and peeling machine: The potatoes are pushed forward by the rotation of the brush and the spiral blade, and at the same time, multiple groups of high-pressure spray water are sprayed on the top to achieve the effect of cleaning and peeling, and the brush can be soft or hard. Applicable to a variety of root fruits and vegetables.

②French fries cutting machine: This machine can efficiently cut potatoes into strips, and the desired cutting size can be achieved by adjusting the blade.

③French fries blanching machine: The French fries are blanched by a continuous blanching machine, so as to achieve the purpose of color protection and ensure that they are more crispy and delicious when fried.

④French fries vibrating water remover: The french fries after blanching need to remove the water on the surface and prevent them from sticking together.

⑤French fries air-drying machine: The surface moisture of french fries is effectively removed by blowing air to prepare for frying, which can shorten the frying time and make the french fries more delicious.

⑥Continuous French Fries Fryer: This machine can fry french fries without interruption. The frying temperature and time can be adjusted according to the demand, and the heating method can be selected. The output per hour is 200-900kg/h.

⑦French fries deoiling machine: use a vibrating deoiling machine to remove the oil on the surface of the fried french fries. The recovered oil can be reused.

⑧French fries quick-freezing machine: The french fries are transported to the quick-freezing machine for freezing, which can prolong the shelf life and facilitate storage. Has high work efficiency.

⑨French fries packaging machine: It can automatically complete the whole process of feeding, measuring, bagging, date printing, nitrogen filling (if necessary), and finished product output. It is a commonly used packaging equipment in the processing of french fries.

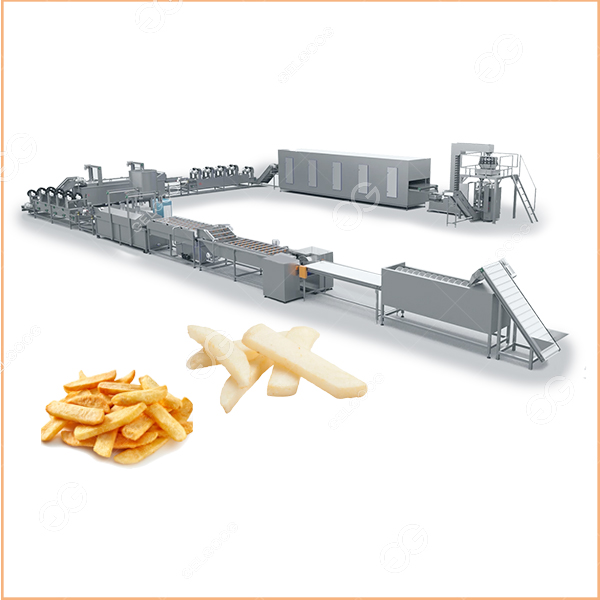

Advantages Of Frozen French Fries Processing Line

- Automatic production, high work efficiency, saving production costs.

- Each machine of the frozen fries production line can be customized.

- Different lines of frozen fries can be ordered according to the output of frozen fries per hour.

- Low energy consumption, multiple functions, high profit, easy to use and maintain.

- It is one of the commonly used processing lines for frozen french fries.

Technical Data

| Product Name | Frozen French Fries Production Line |

| Final Product | Frozen French Fries |

| Raw Material | Fresh potatoes |

| Capacity | 200 kg/h(Can be customized) |

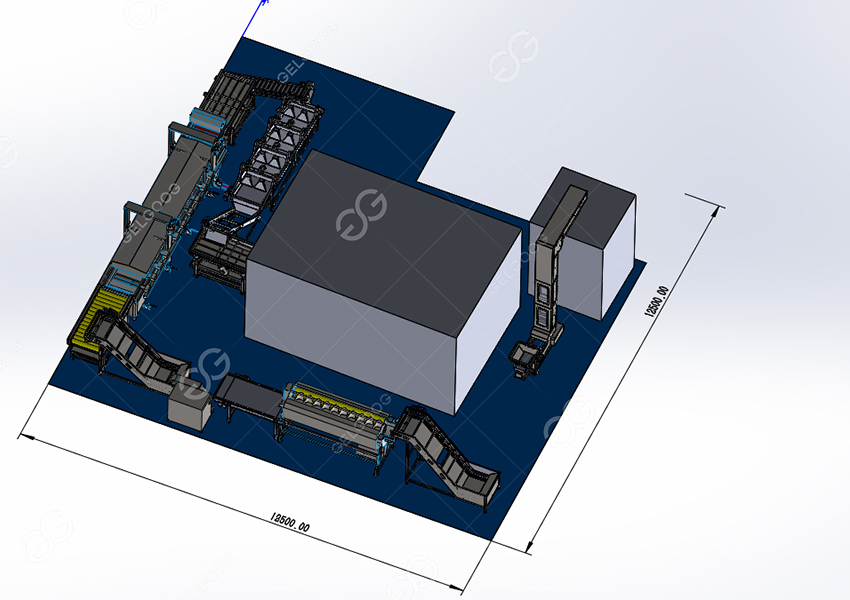

| Working Shop | >300m2, height>4m |

| Voltage | 380/50Hz/3Phase |

| Power | 250kw(Customized) |

| Workers | 6-8 workers |

| Heating | Gas(Can be customized electricity) |

Reviews

There are no reviews yet.