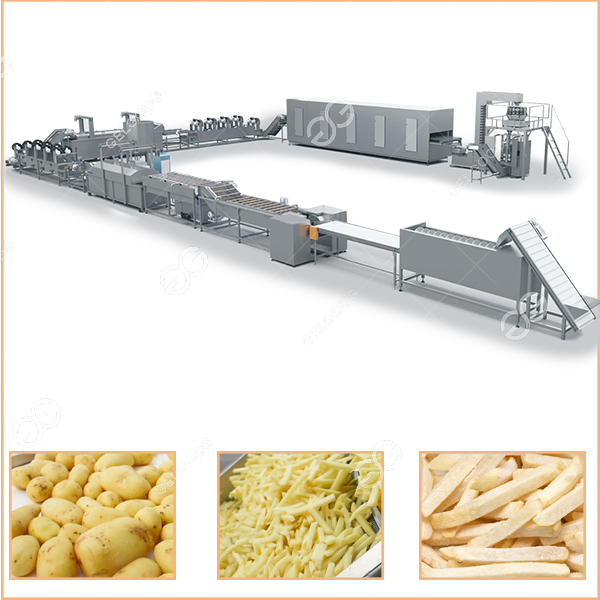

As a professional french fries quick frozen production line machine supplier, we provide customers with quick-frozen french fries solutions of different scales. The whole machine is made of high-quality stainless steel, which is durable, corrosion-resistant, and has a long service life. It is an ideal production line for the processing of quick-frozen french fries.

- Design principle: realize the automatic production of quick-frozen french fries.

- Capacity: 100-1000kg/h, customized according to customer needs.

- Machines: peeling machine, cutting machine, blanching machine, dehydrator, fryer, deoiler, quick freezer, packaging machine

- Material: High quality 304 stainless steel.

- Applicable french fries: frozen fries, frozen corrugated fries.

Advantages of French Fries Production Line Frozen Supplier

- The thickness of the fries can be adjusted (6mm -10mm).

- The french fries quick frozen production line machine can be made according to the special requirements of customers.

- Semi-automatic or fully automatic production lines can be purchased according to demand.

- There are various heating methods for blanching and frying machines: electric or gas.

- It is easy to operate, highly automated, energy-saving, powerful and saves investment.

- The frozen French fries are of good quality, the production line can process high-quality frozen French fries that meet hygienic standards

- Our company provides customers with high-quality services, cost accounting, machine design, machine installation and debugging, etc.

French Fries Quick Frozen Production Line Machine Introduction

- Potato cleaning and peeling machine: This machine can continuously and thoroughly clean and peel potatoes.

- Sorting conveyor: removes defective potatoes.

- French Fries Cutting Machine: Cut potatoes into French fries with adjustable cutting thickness.

- French fries washing machine: impact and scrub the french fries by high pressure water flow and blisters to wash away the starch on the surface

- French fries blanching machine: blanching to inhibit the activity of enzymes and maintain the original bright color of the french fries.

- Vibration dehydrator: remove surface moisture by vibration.

- Air-cooled dryer: Pre-cooling is performed by high-pressure air blowing, and excess water is removed in a short time, effectively preventing the phenomenon of frying oil jumping.

- French Fry Fryer: Deep fry the fries at a stable oil temperature and evenly brown to a golden brown.

- Vibration degreaser: French fries must be deoiled after frying to remove excess frying oil on the surface,

- Cooling: Cool down quickly with a cooling fan, ready for the next step

- French Fries Quick Freezer: Freeze products and prevent sticking to achieve quick freezing.

- Automatic packing machine: used for packing finished frozen French fries.

As a professional french fries production line frozen supplier, we will provide suitable solutions according to your needs, welcome to customize.

Technical Data

| Product Name | Frozen French Fries Production Line |

| Final Product | Frozen French Fries |

| Raw Material | Fresh potatoes |

| Capacity | 200 kg/h(Can be customized) |

| Working Shop | >300m2, height>4m |

| Voltage | 380/50Hz/3Phase |

| Power | 250kw(Customized) |

| Workers | 6-8 workers |

| Heating | Gas(Can be customized electricity) |

Reviews

There are no reviews yet.