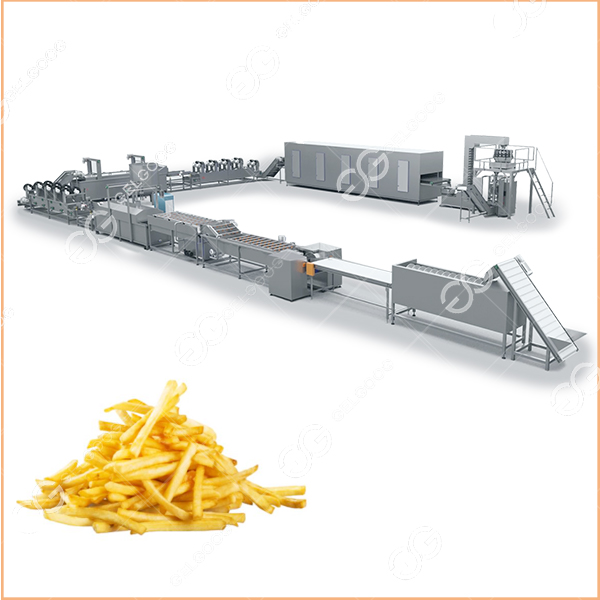

The whole french fries processing plant is made of high-quality stainless steel, which is durable, corrosion-resistant, and has a long service life. Different output can be customized according to customer needs: 100kg/h, 300kg/h, 400kg/h, 500kg/h, 800kg/h, 1200kg/h, 2000kg/h. When making french fries production line, we always consider different characteristics of the potato, the size of the customer’s plant, the size of the output, and other factors, so as to ensure that the most suitable French fries frying solution is found for the customer.

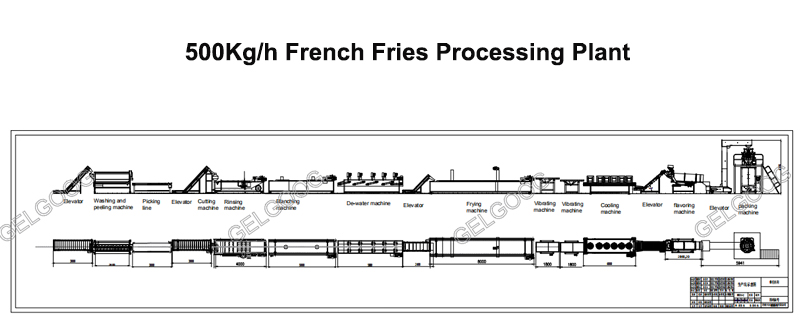

Process Flow of French Fries Production Line

Lifting → Rough washing and removing stone → Peeling → Picking line → Elevator → Slicing → Rinse → Blanching → Air knife air dryer → Elevating → Frying → Vibrating oil draining → Vibrating oil draining → Air cooling cooler → Elevator → Roller seasoning → packaging

Introduction of French Fries Processing Machine

- Lifting: lift the potatoes to the thickness and fine stone removal equipment (use the baffle lifter).

- Rough washing: rough drum washing and removing stone debris, etc. (use drum pre-washing stone removal machine).

- Peeling: Clean and peel the potatoes, which is efficient and energy-saving (use a U-shaped potato brush cleaning machine).

- Picking: Pick and trim the peeled potatoes.

- Upgrade: Upgrade to high-efficiency french fries cutting machine.

- Cutting: After picking, the potatoes are cut into strips with high efficiency, and the size is adjustable (select high-efficiency French fries cutting machine).

- Rinse: Clean the starch on the surface of the fries (use a bubble cleaning machine)

- Blanching: The french fries are blanched to inhibit the activity of active enzymes and protect the color (choose the French fries continuous blanching machine).

- Vibrate and drain: remove the scraps that are too small, and vibrate to remove excess water (use a vibrating water remover)

- Frying: frying to color, and optimize texture and taste (use continuous french fries frying machine)

- Deoiling: Vibrate to remove excess oil (choose French fries vibrating oil drainer)

- Air-cooled cooling: The air-cooled line removes oil to cool down, blows off the excess oil on the surface, and fully cools the fries (use an air-cooled machine)

- Seasoning: season the fried fries (use a drum seasoning machine)

- Packing: according to the customer’s request packaging weight (multi-head weighing packaging machine is selected)

Advantage of French Fries Processing Plant

- Can be tested and debugged at the factory.

- A machine with powerful functions, low maintenance cost, and high quality.

- The obtained fries are of good quality and can effectively reduce waste and waste.

- French fries processing machines and production processes tailored to your personal wishes and needs.

- Professional engineers and the R&D departments cooperate to determine the best solution for each project, insist on co-creating with customers all the time.

If you want to engage in the french fries processing business, come and customize this french fries processing plant. leave us a message, we will send you a detailed plan and quotation as soon as possible.

Technical Data

| Item | Parameter |

| 1, Elevator | 0.75kw/380v/50Hz 2000*800*2000mm |

| 2, Cleaning and Peeling Machine | 4.75kw/380v/50Hz 1800*900*1500mm |

| 3, Sorting Conveyor | 0.75kw/380v/50Hz 3000*900*900mm |

| 4, Potato Chips Cutting Machine | 1.5kw/380v/50Hz 950*800*950mm |

| 5, Rinshing Machine | 5kw/380v/50Hz 3500*1600*900mm |

| 6, Blanching Machine | 70kw/380v/50Hz 3500*1600*950mm |

| 7,Vibrating and Water Removing Machine | 1.5kw/380v/50Hz 1500*1000*1300mm |

| 8,Sorting Conveyor | 0.75kw/ 380V/50Hz 4000*800*1000mm |

| 9, Air Cooling and water removing machine | 15kw/380v/50Hz 4000*1200*1400mm |

| 10,Elevator | 0.75kw/380v/50hz 2500*800*1300mm |

| 11, Electric Continuous Fryer Machine | 120kw/380v/50Hz 4000*1200*2600mm |

| 12, Vibrating and Oil Removing Machine | 1.5kw/380v/50Hz 1500*1000*1300mm |

| 13,Air Drying Machine | 8kw/380v/50Hz 4000*1200*1600mm |

| 14,Elevator | 0.75kw/380v/50Hz 2400*800*2200mm |

| 15,Flavoring Machine | 50kw/380v/50hz 2500*900*1500mm |

Reviews

There are no reviews yet.