Crafted with precision engineering and cutting-edge technology, this potato chip manufacturing equipment is tailored to meet the demands of large-scale potato chip production. From cleaning to packaging, every step of the process is seamlessly integrated, eliminating manual labor and ensuring consistent results batch after batch.

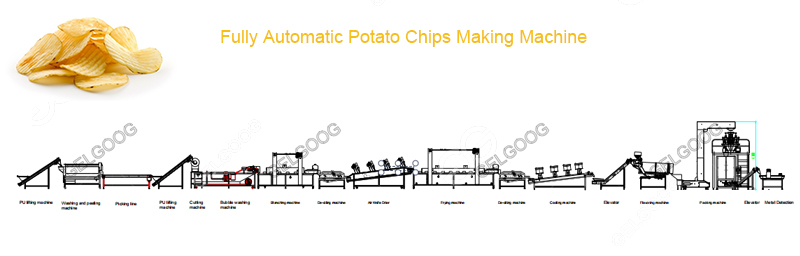

Potato Chips Processing Machine Working Process:

cleaning → peeling → slicing → blanching → air drying → frying → deoiling → cooling → packing

Potato cleaning and peeling machine: It adopts brush type cleaning and peeling, which can complete the cleaning and peeling work at the same time. High efficiency and low loss.

Slicing: The potatoes are then sent to the slicing machine to complete the slicing process, and the slice thickness can be adjusted between 1-8mm.

Blanching: The potato slices will be sent to the blanching machine. The purpose of blanching is to remove the starch on the surface of the potato slices and make the potato slices crispier.

Air drying: This process is to remove moisture from the surface of the potato slices to achieve a better frying effect.

Frying: The potato slices expand rapidly in the hot oil and become crispy and golden.

De-oiling: Excess oil is separated by centrifugation or vibration to make the potato chips healthier.

Cooling: Make sure the potato chips are completely cooled before packaging to avoid heat causing deformation of the packaging material.

Potato Chip Manufacturing Equipment Key Features:

Automatic operation: These potato chips processing machine handles everything from potato loading to packaging with minimal human input, maximizing productivity and reducing labor costs.

Large scale: We can customize the potato chips processing flow according to the actual needs of customers. Different configurations have different capacity, ranging from 100-2000kg/h.

High-speed slicing: Equipped with advanced slicing mechanisms, it swiftly transforms potatoes into uniform slices of the desired thickness, ensuring even cooking and perfect texture in every chip.

Precise frying control: Maintain precise control over frying parameters, guaranteeing crispy and golden-brown chips every time. The automated frying system ensures consistent quality across all batches.

Oil management system: Minimize oil wastage and maintain hygiene standards with an integrated oil management system that regulates oil usage, filtration, and replenishment, enhancing operational efficiency and cost-effectiveness.

These potato chip manufacturing equipment can also be used for making french fries by changing some machines, If you want to produce different products, please let us know in advance.

Reviews

There are no reviews yet.