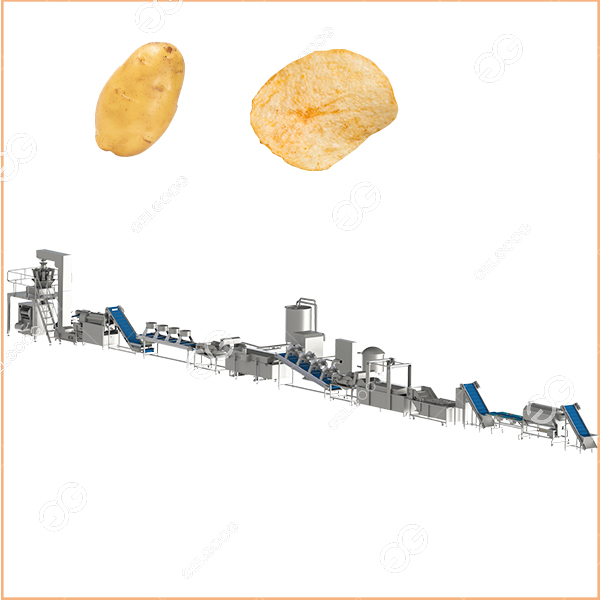

Hashed brown potatoes are a popular American breakfast food, typically made from potatoes as the main ingredient. They are processed into a patty shape, then deep-fried until golden brown and crispy on the outside and soft on the inside, with a rich potato flavor. This hashed brown potatoes processing line is specifically designed for the automatic and continuous production of hashed brown potatoes. A hashed brown potatoes processing line is a complete production system that continuously performs processes such as washing, peeling, slicing/shredding, blanching, seasoning, forming, and frying using mechanized and automated equipment. This production line can be flexibly configured according to the customer’s finished product form, production capacity requirements, factory conditions, and processing habits, and is suitable for small and medium-sized food factories to large-scale industrial production enterprises.

Hashed Brown Potatoes Production Process:

1. Potato Washing and Peeling

Before processing, fresh potatoes need to be cleaned to remove surface impurities. The potato skins are then removed using brushes or steam to ensure a smooth surface, facilitating subsequent cutting and processing.

2. Shredding / Chopping

Depending on the type of potato product, either shredding or chopping can be selected. The width, length, and thickness of the shredded potatoes are adjustable, ensuring uniform and consistent potato shreds. Precise cutting helps improve the texture consistency and shaping of the hashed brown potatoes.

3. Blanching

The cut potato strips or pieces usually require blanching. The blanching time and temperature can be precisely controlled according to the potato variety and product requirements.

4. Seasoning and Mixing

After blanching and draining, the ingredients enter the seasoning process. Salt, spices, onion powder, and other ingredients are mixed evenly to ensure consistent flavor in every hashed brown potatoes.

5. Shaping

The seasoned material enters the hashed brown potato forming machine, where it is pressed into hashed brown potatoes of a fixed shape and thickness using molds.

6. Frying

The formed hashed browm are placed in a deep fryer. By controlling the oil temperature and frying time, the hashed brown potatoes quickly set and develop a golden-brown surface.

Hashed Brown Potatoes Processing Line Features:

1. Highly customizable process

We can flexibly adjust the production process configuration according to the customer’s product positioning and process requirements, truly achieving “customization on demand,” avoiding equipment redundancy, and improving return on investment.

2. Food-grade design, safe and reliable

The hashed brown potatoes processing line is made of SUS304 stainless steel, with a reasonable structure, easy to clean and maintain, complying with food processing hygiene standards, and suitable for long-term stable operation.

3. Support for factory planning and overall solution design

In addition to supply hashed brown potatoes equipment, we can also provide our customers with: factory layout planning suggestions, process flow design, capacity matching, and equipment selection. We help customers achieve an efficient and smooth overall production layout from “raw materials entering the factory” to “finished products leaving the factory.”

Reviews

There are no reviews yet.