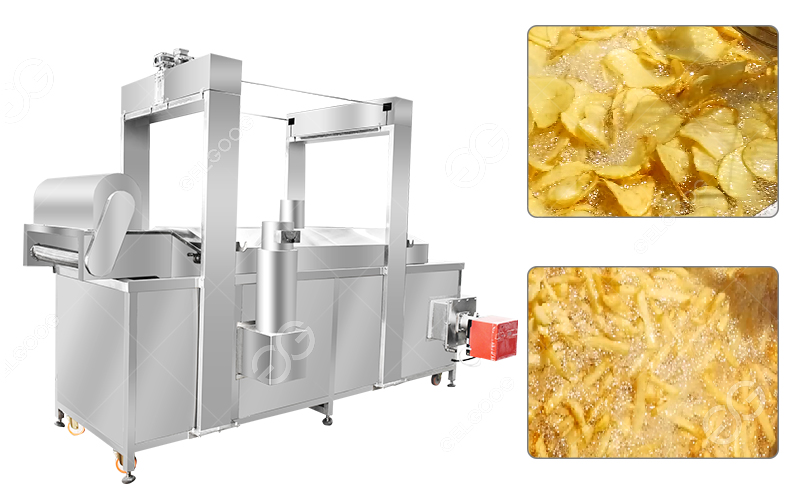

Potatoes are often processed into French fries or potato chips. The whole finger chips frying machine of finger potato chip fryer provided by our company is made of stainless steel, which has high thermal efficiency, saves fuel consumption and can save energy. There is no carbonation during frying. In addition, the output of this finger chips making machine per hour is between 200kg/h-1000kg/h of lotus root, and it supports customization!

Structural Features Of Finger Chips Frying Machine

- The whole finger chips machine is composed of a belt conveying system, lifting system, automatic slag scraping system, automatic control system, hot oil circulation system, heating system and smoke exhaust system.

- Aluminum silicate insulation material is installed before the shell and body to reduce heat loss.

- Equipped with automatic temperature controller, double-layer mesh belt conveying materials, automatic lifting system.

- Equipped with a sight glass, sewage outlet, PLC control panel, filter screen, oil storage tank, and oil filter device.

- There are pulleys at the bottom for easy movement.

Competitive Advantages Of Finger Chips Making Machine

- High working efficiency, has a long service life and can be customized.

- Automatic discharge and automatic feeding. The fried finger chips are of stable quality.

- The heat source of this machine can be electricity and gas.

- Oil can be recycled and reused, no need to change the oil every day, saving cost.

- Frying temperature and frying time can be freely adjusted according to different fried foods, and can fry a variety of materials at the same time.

- Fry evenly, without carbonization, ensure a clean and hygienic working environment and achieve constant temperature continuous production.

- This potato finger chips making machine can be used with a deoiling machine and is also commonly used in french fries production lines and potato chip production lines.

Working Video Of Potato Finger Chips Making Machine

Finger chips enter the machine between two mesh belts, preventing food from floating and making frying more even. This kind of fryer has a higher fuel-saving rate than ordinary frying machines, saving 50% to 60% of fuel.

Operation Steps Of Finger Chips Frying Machine

- Clean up the inside of the chips frying machine, remove foreign matter, dirt, and dry the water.

- Check whether the power cord, switch, indicator light, connector and motor are normal.

- Close the oil discharge valve and the slag discharge valve.

- Add water to the oil tank through the upper part of the oil tank, and inject oil from the upper part of the oil tank.

- Connect the cooling water to the cooling water connector, and keep the cooling water connected during operation.

- Turn on the power.

- Turn on the heating knob switch to start heating.

- When the oil temperature reaches the set temperature, turn on the mesh belt motor to make the conveyor belt starts running.

- Set the frying time, put finger chips into the inlet to fry.

- After the work is completed, turn off the power and close the cooling water valve.

If you want to get more details about this potato finger chips making machine, you can leave us a message!

Technical Parameter Of Finger Chips Frying Machine

| Model | Belt width (mm) |

oil pump power (kw) |

lifting power (kw) |

heating power | Dimension (mm) |

| GGLZG3500A | 800 | 1.5 | 0.55 | 20Wkcal | 3700*1900*2400 |

| GGLZG5000A | 800 | 1.5 | 0.55*2 | 30Wkcal | 5200*1900*2400 |

| GGLZG6500A | 800 | 1.5 | 0.75*2 | 20Wkcal*2 | 6700*1900*2400 |

| GGLZG8000A | 800 | 2.2 | 0.75*2 | 30Wkcal*2 | 8200*1900*2400 |

| GGLZE3500A | 800 | 1.5 | 0.55 | 90KW | 3700*1600*2200 |

| GGLZE5000A | 800 | 1.5 | 0.55*2 | 120kw | 5200*1600*2200 |

| GGLZE6500A | 800 | 1.5 | 0.75*2 | 190kw | 6700*1600*2200 |

| GGLZE8000A | 800 | 2.2 | 0.75*2 | 255kw | 8200*1600*2200 |

Reviews

There are no reviews yet.