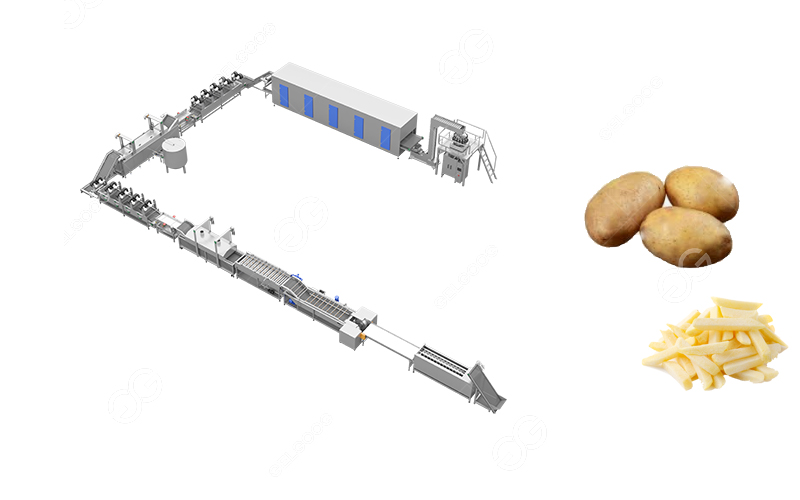

Frozen french fries have become a staple in households worldwide, offering convenience without sacrificing flavor. In this article, we will talk about how are frozen french fries processed in factory.

1. Selection of potatoes:

It all begins with the selection of high-quality potatoes. Potatoes are chosen based on specific characteristics such as size, shape, and sugar content, which can affect the taste and texture of the final product.

2. Washing and peeling:

Once selected, the potatoes undergo a thorough washing process to remove any dirt and debris. Next, they are mechanically peeled to remove the skin, ensuring a uniform appearance for the fries.

3. Cutting:

After peeling, the potatoes are precisely cut into the familiar french fry shape. This is typically done using specialized machinery equipped with sharp blades that slice the potatoes into consistent dimensions, ensuring uniformity in size and shape.

4. Blanching:

Blanching is a crucial step in the process, where the cut fries are briefly submerged in hot water or steam. This helps to partially cook the fries, removing excess sugars and starches from the surface, which can cause them to stick together during freezing. Blanching also helps to preserve the natural color of the potatoes and extend their shelf life.

5. Drying:

Following blanching, the fries are dried to remove excess moisture. This is essential for achieving the desired crispiness when the fries are eventually cooked. The drying process may involve passing the fries through a series of air blowers or using centrifugal force to remove water.

6. Pre-frying:

Some manufacturers opt to pre-fry the fries before freezing them. Pre-frying involves partially cooking the fries in oil at a high temperature for a short period. This creates a crispy exterior layer that helps to retain moisture and flavor during freezing and subsequent cooking.

7. Freezing:

Once prepped, the fries are rapidly frozen to lock in freshness and flavor. This is typically done using a blast freezer, which exposes the fries to extremely low temperatures in a short amount of time. Quick freezing prevents the formation of large ice crystals, preserving the texture and taste of the fries.

8. Packaging:

After freezing, the fries are packaged into bags or cartons suitable for retail distribution. Packaging materials are carefully chosen to maintain product quality and prevent freezer burn during storage. Some packages may also include special coatings or liners to enhance freshness and extend shelf life.

9. Distribution:

Once packaged, the frozen french fries are ready to be distributed to retailers, restaurants, and foodservice establishments worldwide. They are transported in temperature-controlled environments to ensure they remain frozen until they reach their final destination.

10. Cooking:

Finally, it’s time to cook and enjoy the frozen french fries! Whether baked, fried, or air-fried, these convenient treats can be prepared in a variety of ways to suit individual preferences. With their crispy exterior and fluffy interior, frozen french fries are a beloved snack or side dish enjoyed by people of all ages.

In conclusion, the journey of frozen french fries from farm to table involves a series of carefully orchestrated steps to ensure quality, consistency, and flavor. From selecting the finest potatoes to freezing and packaging, each stage of the process plays a crucial role in delivering the perfect fry every time. If you want to start the business, we can supply you the frozen french fries machine.